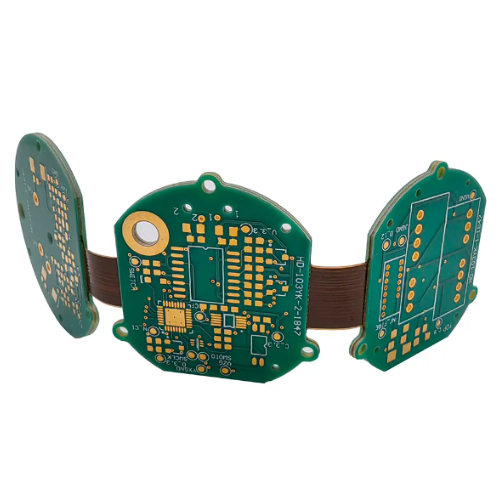

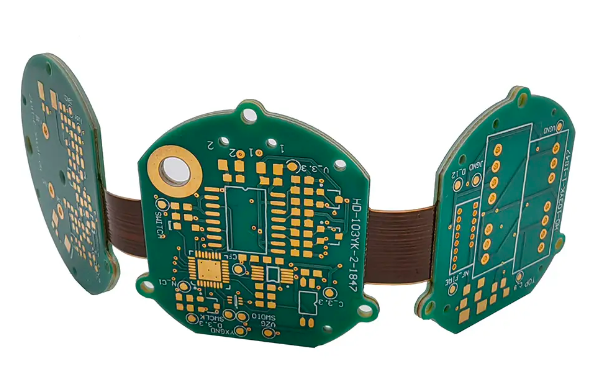

Rigid-Flex PCB

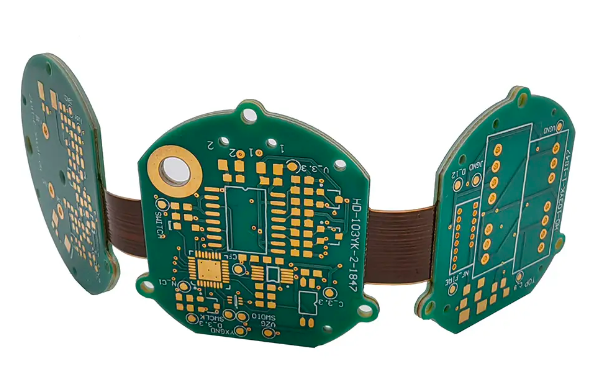

Rigid-Flex PCB Manufacturing

Smart Chiplink RIGID-FLEX PCB CAPABILITIES

|

Thickness of Finished Product ( Flex Part, No Stiffener ):

|

0.05-0.5mm ( Ultimate:0.5-0.8mm )

|

|

Thickness of Finished Product ( Rigid Part ):

|

0.2-6.0mm

|

|

Finished Copper Thickness:

|

0.5-5 OZ

|

|

Min Tracing/Spacing:

|

3mil / 3mil

|

|

Surface Finish:

|

HASL/OSP - RoHS

ENIG / Hard Gold / Immersion Silver

|

|

Impedance Control:

|

310%

|

|

Min Laser Hole:

|

0.1mm

|

|

Min Drilling Hole Diameter:

|

8mil

|

|

Other Techniques:

|

HDI

Gold Fingers

Stiffener ( Only for PI / FR4 Substrate )

|

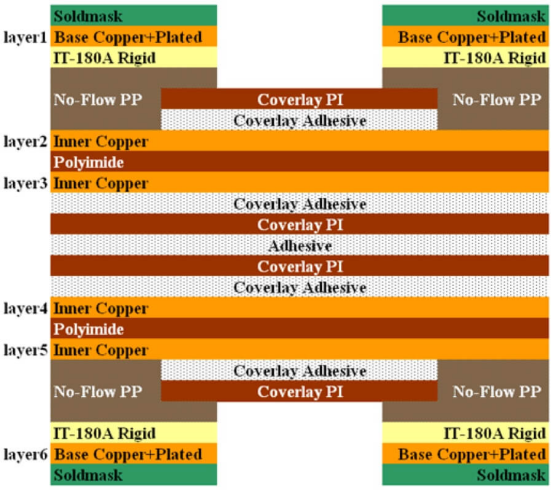

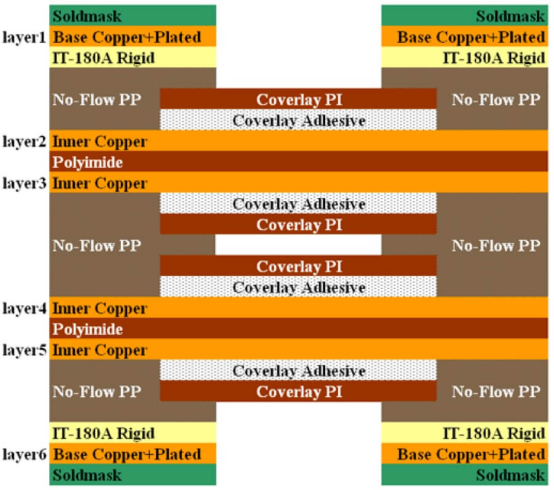

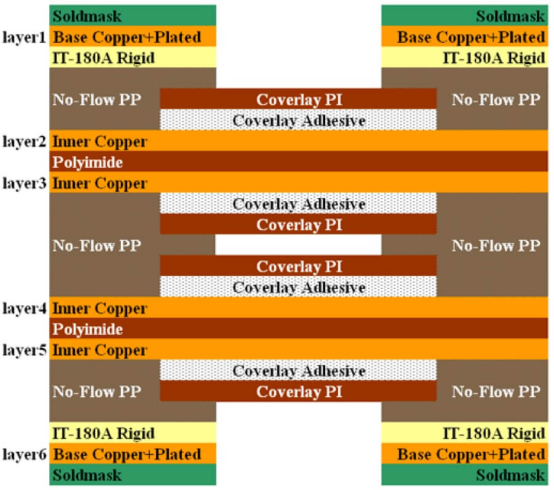

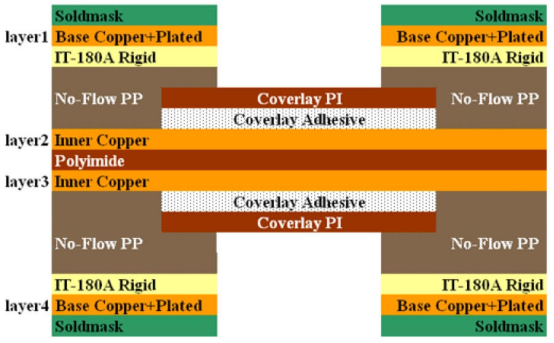

RIGID-FLEX PCB STACK-UP STRUCTURES AND DESIGN

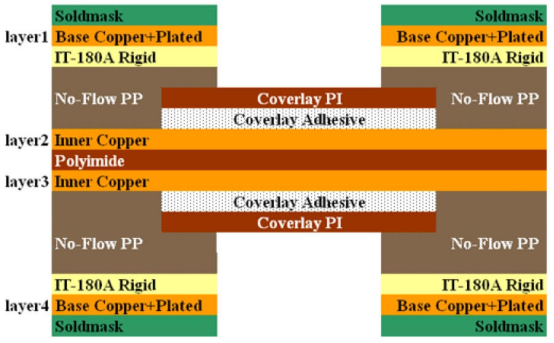

Non-lamination flex&rigid board :

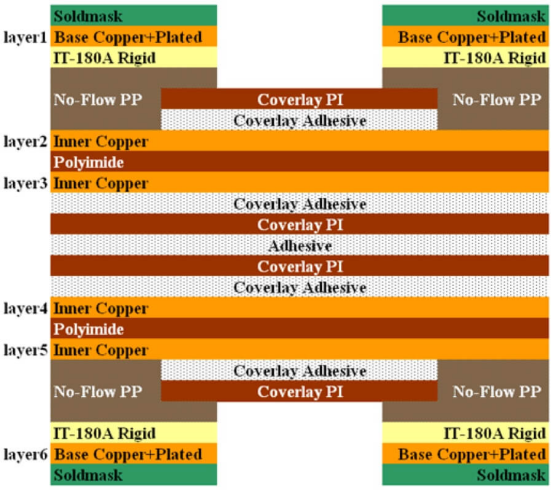

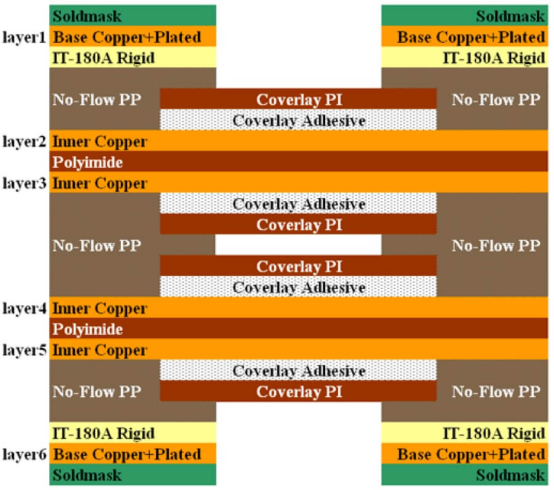

Lamination flex&rigid board :

Flex layer in Inner layer :

Flex layer on outlayer :

MATERIALS OF RIGID-FLEX PCBS

|

Conductors

|

·Rolled annealed ( RA ) copper

·Electro deposited ( ED ) copper

|

|

Adhesives

|

. Epoxy

·Acrylic

·Pre-preg

·Pressure Sensitive Adhesive ( PSA )

·Adhesiveless base material

|

|

Insulators

|

·FR-4

·Polyimide

·Polyester, Polyethylene Naphthalate ( PEN ), and Polyethylene

·Terephthalate ( PET )

·Solder mask/Flexible solder mask

·Photo image-able cover lay ( PIC )

|

|

Finishes

|

·Solder ( Tin / Lead or RoHS compliant ) Tin

·Immersion Nickel / Gold / Silver

·Hard Nickel / gold

·OSP

|

rigid flex pcb manufacturing process

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski Српски

Српски 简体中文

简体中文 Беларус

Беларус