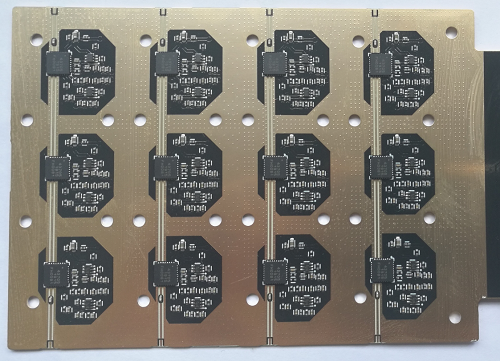

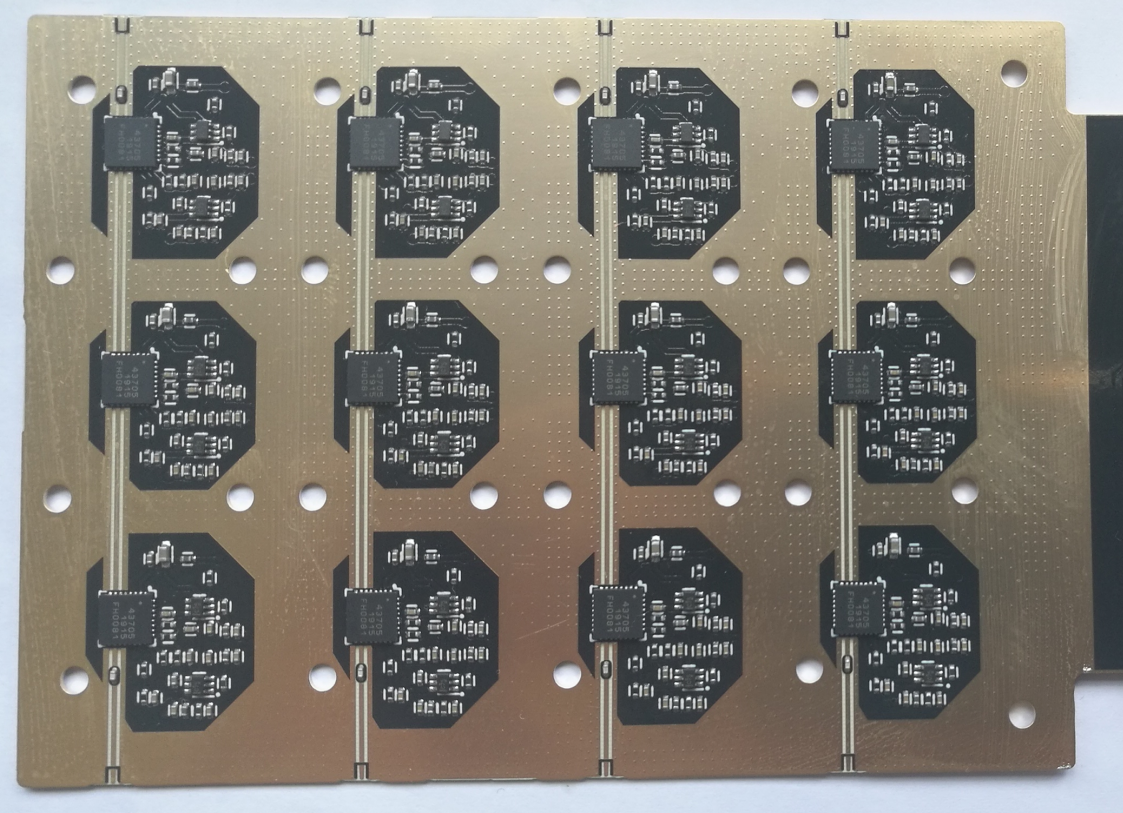

Rogers PCB Suppliers

rogers pcb board material

Rogers PCB

√ The Rogers PCB is a special type of PCB made with high-frequency material.

√ The PCB also comes with a stable temperature and a high-quality dielectric constant, making it stand out.

√ The thermal expansion coefficient of the PCB is similar to copper foil—used to enhance the PTFE substrate.

√ Rogers PCB is ideal for high-frequency and high-speed circuits—as well as RF products and microwaves.

THE DIFFERENT TYPES OF ROGERS PCB

|

Rogers 4350B

|

The Rogers 4350B has a low loss capability and stable control on its dielectric constant (DK) — which makes its materials ideal for high power RF designs and super-active appliances.

|

|

Rogers 4003

|

The Rogers 4003 model uses 1674 and 1080 glass fabric styles. All its configurations have the same specifications; they don’t support bromination.

|

|

Rogers 4835

|

This 4835 laminate is a low-loss material that provides high stability at significant oxidation resistance and increased temperatures. With it, you’ll get standard glass or epoxy FR-4 processes and cheap circuit production.

|

|

Rogers 4360G2

|

This laminate offers a perfect balance of processing capability and performance. Plus, the low-loss laminate consists of hydrocarbon ceramic-filled thermostat materials.

|

|

Rogers 3003

|

This Rogers PCB model is suitable for automotive radar applications with 77 GHz and it also supports 5G wireless applications and ADAS.

|

|

Rogers 3006

|

The 3006 model offers excellent mechanical and electrical stability—with a reliable dielectric constant across various temperatures. And it removes the step change in the Dk.

|

|

Rogers 3010

|

The 3010 is one of the most affordable models with advanced ceramic-filled PTFE materials. Hence, its stability streamlines the broadband components.

|

|

Rogers 0588

|

Reinforced with glass microfibers, the Rogers 5880 has a low DK and loss feature. Hence, it makes the model highly suitable for broadband and high-frequency applications.

|

|

Rogers 6002

|

The 6002 model comes with low DK materials that are ideal for sophisticated microwave structures. Hence, it's ideal for multi-layer board designs.

|

|

Rogers 6010

|

This RO6010 is ideal for microwave and electronic board applications that require a high DK. Also, the model is ideal—if you plan on dealing with circuit size reduction.

|

Data Sheet Showing the Different Roger PCB Models (Table 1)

|

Property

|

RO4350B

|

RO3003

|

RO3006

|

RO3010

|

RO4835

|

RO5880

|

RO6002

|

RO6010

|

RO4003

|

RO 4360G2

|

|

Dk, Process

|

(2)3.48

± 0.05

|

3.00

± 0.04

|

6.15

± 0.15

|

10.2

± 0.30

|

3.48

± 0.05

|

2.20

± 0.02

|

2.94

± 0.04

|

10.2

± 0.25

|

3.38

± 0.05

|

6.15

± 0.15

|

|

Dk Design

|

3.66

|

3.00

|

6.50

|

11.20

|

3.66

|

2.20

|

2.94

|

-

|

3.55

|

-

|

|

Dissipation Factor

|

0.0037

0.0031

|

0.001

0

|

0.002

0

|

0.002

2

|

0.003

7

|

0.0004

0.0009

|

0.001

2

|

0.002

3

|

0.0027

0.0021

|

0.003

8

|

|

Thermal Coefficient

|

+50

|

-3

|

-262

|

-395

|

+50

|

-125

|

+12

|

-425

|

+40

|

-

|

|

Dimension Stability

|

-

|

-0.06

0.07

|

-0.27

-0.15

|

-0.35

-0.31

|

-

|

-

|

-

|

-

|

-

|

-

|

|

Volume Resistivity

|

1.2 X 10^10

|

10^7

|

10^5

|

10^5

|

5 x 10^8

|

2 x 10^7

|

10^6

|

5 x 10^5

|

1.7 X 10^10

|

4.0 x 10^13

|

|

Surface Resistivity

|

5.7 X 10^9

|

10^7

|

10^5

|

10^5

|

7 x 10^8

|

3 x 10^7

|

10^7

|

5 x 10^6

|

4.2 X 10^9

|

9.0 x 10^12

|

|

Electrical Strength

|

31.2

(780)

|

-

|

-

|

-

|

30.2

(755)

|

0.96

(0.23)

|

-

|

-

|

31.2

(780)

|

784

|

|

Tensile Modulus

|

16,767 (2,432)

14,153, (2,053)

|

930

823

|

1498

1293

|

1902

1934

|

7780

(1128)

|

1070 (156) 450 (65), 860 (125) 380 (55)

|

828 (120)

|

931 (135)

|

19,650 (2,850) 19,450 (2,821)

|

-

|

Table 2 (Continuation)

|

Property

|

RO4350B

|

RO3003

|

RO3006

|

RO3010

|

RO4835

|

RO5880

|

RO6002

|

RO6010

|

RO4003

|

RO 4360G2

|

|

Tensile Strength

|

203 (29.5)

130 (18.9)

|

-

|

-

|

-

|

136 (19.7)

|

-

|

-

|

17 (2.4)

|

139 (20.2)

100 (14.5)

|

131 (19)

97 (14)

|

|

Flexural Strength

|

255 (37)

|

-

|

-

|

-

|

186 (27)

|

-

|

-

|

4364 (633)

|

276 (40)

|

213 (31)

145 (21)

|

|

Dimensional Stability

|

<0.5

|

-

|

-

|

-

|

<0.5

|

-

|

-

|

-

|

<0.3

|

-

|

|

Coefficient of Thermal Expansion

|

10

12

32

|

17

16

25

|

17

17

24

|

13

11

16

|

10

12

32

|

31

48

237

|

16

16

24

|

24

24

24

|

11

14

46

|

13

14

28

|

|

Tg

|

>280

|

-

|

-

|

-

|

>280

|

-

|

-

|

-

|

>280

|

>280

|

|

Td

|

390

|

500

|

500

|

500

|

390

|

500

|

500

|

500

|

425

|

407

|

|

Specific Heat

|

-

|

0.9

|

0.86

|

0.8

|

-

|

-

|

0.93 (0.22)

|

1.00 (0.239)

|

-

|

-

|

|

Thermal Conductivity

|

0.69

|

0.50

|

0.79

|

0.95

|

0.66

|

0.22

|

0.60

|

0.78

|

0.71

|

0.75

|

|

Moisture Absorption

|

0.06

|

0.04

|

0.02

|

0.05

|

0.05

|

0.02

|

0.02

|

0.05

|

0.06

|

0.08

|

|

Density

|

1.86

|

2.1

|

2.6

|

2.8

|

1.92

|

2.2

|

2.1

|

3.1

|

1.79

|

2.16

|

|

Copper Peel Strength

|

0.88 (5.0)

|

12.7

|

7.1

|

9.4

|

0.88 (5.0)

|

31.2 (5.5)

|

8.9 (1.6)

|

12.3 (2.1)

|

1.05 (6.0)

|

5.2 (0.91)

|

|

Flammability

|

(3)V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

94V-0

|

N/A

|

V-0

|

|

Lead-Free Process Compatible

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

-

|

ROGERS MATERIAL VS. FR-4 MATERIAL

|

Factors

|

Rogers Material

|

FR-4 Material

|

|

Dissipation factor (DF)

|

0.004

|

0.020

|

|

Price

|

Expensive

|

Affordable

|

|

Thermal Management

|

The Rogers material manages high temperatures perfectly.

|

This grade material doesn’t handle high temperature well.

|

|

Performance

|

Remarkable

|

Decent

|

|

Dielectric Constant (DK)

|

6.15 to 11

|

4.5

|

|

Impedance Stability

|

Higher polarity and stabilizes charges effectively.

|

Lower polarity and it doesn’t stabilize charges well.

|

|

Applications

|

Rogers is a better option for space applications because it reduces outgassing effectively.

|

The FR-4 isn’t so ideal for space applications because it isn’t outgassing tolerant.

|

Depending on the type of materials that you need, rest assured of finding them at Smart Chiplink. We have a team of experts that can guarantee you an unforgettable manufacturing experience using Rogers and FR-4 materials.

For more details about PCB materials, feel free to contact our support team via [email protected].

Rogers PCB Manufacturers

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski Српски

Српски 简体中文

简体中文 Беларус

Беларус